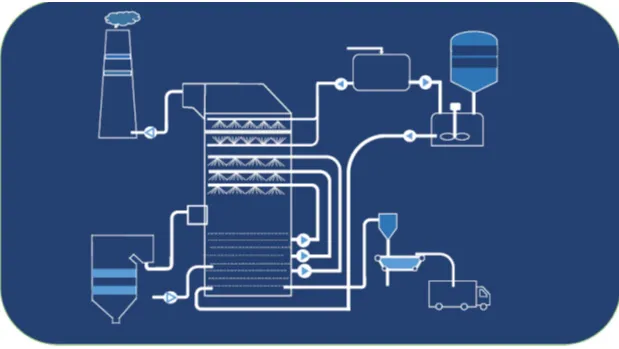

FLUE GAS DESULFURIZATION

FGD – Wet

We design absorber design features provide the highest levels of SO2 removal, reduced operating costs and

significant

reductions in maintenance costs compared to other technologies. These benefits allow our customers to stay

competitive

with today’s increasingly more stringent environmental requirements.

Our Wet FGD systems are of counter- current flow design. Spray headers with suitable nozzles are provided

at multiple

levels to ensure complete coverage of the absorber cross-sectional area. Flue gases moves upward in the

absorber and

comes in contact with reagent slurry, which is sprayed downward through the nozzles. This results in

efficient gas

scrubbing. Limestone, Quick lime or Caustic soda can be used as the reagent.

The dosing of reagent in to the system is automatically controlled to achieve the required SO2 removal efficiency.

Moisture separators with high efficiency are provided to prevent slurry carryover and deposition in the downstream of the system.

Advantages Proven Technology

- High Sulphur Dioxide removal efficiency

- Consumption of Reagent is close to stoichiometric ratio

- Can accommodate sudden surge in flue gas volume and Sulphur Dioxide concentration.

- Gypsum can be produced as a byproduct.

- Easy and Trouble free operation